Product recommendation

Hongyuan Metal is a high-tech private enterprise specializing in the production of High corrosion-resistant aluminum alloy Multi-Port Extrusion Tube(MPE),Precision Drawn Tube,Helical Tube for automotive air conditioners, household air conditioners, wind power generation, cooling and heating, and other industries.

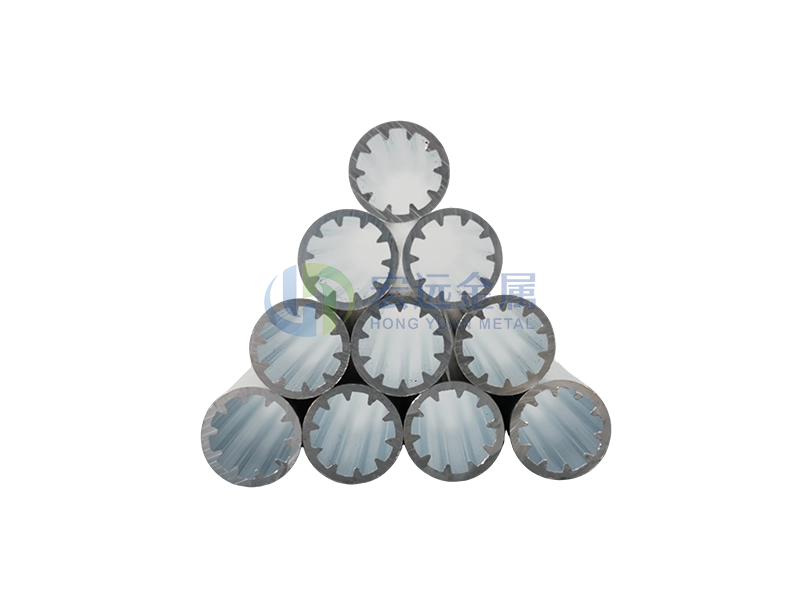

Applications: condensers evaporators. oil clooers, charge air coolers, radiators heaters chillers Alloy 1050/1100/1197/3026/3102/3103/3003 mod Dimension: Width:6-111mm Thickness:0.8-8mm Wall thickness :≥0.2mm

Application: Air cooler . Alloy: 1050/1060/1070/3A21/LF21/3003/6063 and special alloy for improving corrosion resistance . Dimension: OD:20-110mm Thickness:0.3-8mm

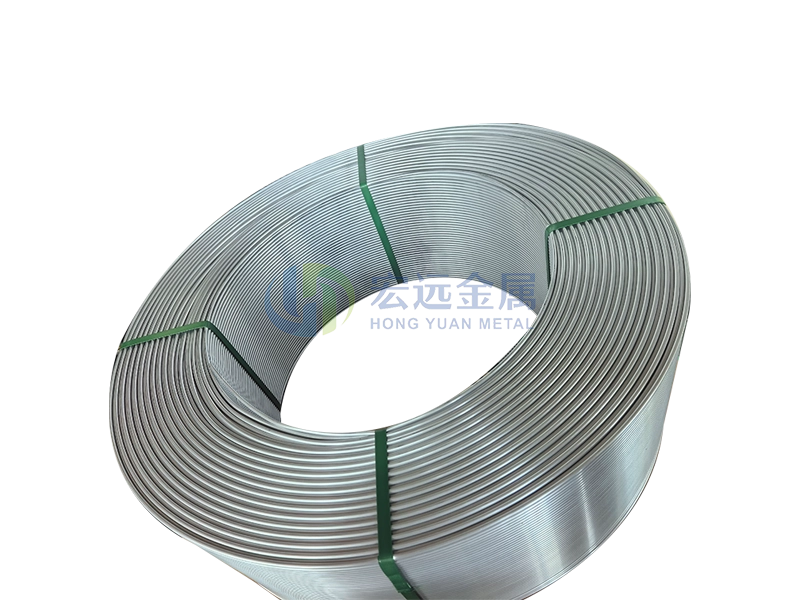

Application: AC connecting pipe . Condenser Evaporator Coolant lines Alloy: 1050/1060/1070/3A21/LF21/3003/6063 and special alloy for improving corrosion resistance . Dimension: OD:2-110mm Thickness:0.3-8mm Temper: Y H12-H18 O

Application: AC connecting pipe . Condenser Evaporator Coolant lines Alloy: 1050/1060/1070/3A21/LF21/3003/6063 and special alloy for improving corrosion resistance . Dimension: OD:2-110mm Thickness:0.3-8mm

MPE tube with Silflux coating Applications: condensers evaporators. oil clooers, charge air coolers, radiators heaters Alloy 1050/1100/1197/3026/3102/3103/3003 mod Dimension: Width:6-111mm Thickness:0.8-8mm Wall thickness :≥0.2mm

Advantages

With 17 years of aluminum tube production capacity, the core production, technology, and quality team are stable, and many experts and professors in the industry are hired for technical support.

Cost advantage

Aluminum ingots are purchased nearby, and all production processes are independently processed without outsourcing, ensuring cost control.

Technical advantage

With 17 years of aluminum tube production capacity, the core production, technology, and quality team are stable, and many experts and professors in the industry are hired for technical support.

Raw material advantage

It has a complete set of equipment for aluminum rod smelting, self-made aluminum rods, and the ability to independently develop new alloys.

Personnel team advantage

Company personnel have received IATF 16949 five-tool training, German automotive industry management VDA6.3, VDA6.5 training, and passed audits from major domestic and foreign automakers.

Production and delivery advantage

Shandong hongyuan has multiple production lines to meet customers' delivery requirement ,honyuan is located in the North of China,nearby Tianjin port ,Qingdao port and Rizhaoport ,very convenient to ship to various countries.

OUR ADVANTAGES

OUR ADVANTAGES

OUR ADVANTAGES

Production line

The company's production and inspection equipment is all imported from Italy, Japan, Germany, the United States, etc., and the workshop production lines have all realized fully automatic and semi-automatic production and management.

Flux coating line

Extrusion line

Cutting line

Round pipe extrusion line

Homogeneous group

Melting Aluminum Group

Hongyuan Metals

Shandong Hongyuan Metal Material Co., Ltd.

Shandong Hongyuan Metal Material Co., Ltd. is a high-tech private enterprise specializing in the production of highly corrosion-resistant aluminum alloy multi-porous extruded flat tubes, precision-drawn round tubes, and internal threaded tubes for enterprises such as automobile air conditioners, household air conditioners, and wind power generation refrigeration and heating. It has become a member unit of the China Refrigeration Society, a member unit of the Thermal System Branch of the China Automotive Industry Association, and a member unit of the China Household Electrical Appliances Association. The company's production and inspection equipment is all imported from Italy, Japan, Germany, the United States, etc., and the workshop production lines have all realized fully automatic and semi-automatic production and management. The advanced and complete testing facilities are equipped, the process control is strictly stable, and it has international-level research and development and testing, high-precision image measuring instruments, X-ray fluorescence film thickness measuring instruments to determine the zinc content and thickness uniformity of galvanized pipes, electronic tensile testing machines to test the mechanical properties of finished aluminum pipes, and roughness measuring instruments to measure the roughness of aluminum pipes, etc., ensuring the quality control ability of the production process. The annual output of various aluminum materials is more than 30,000 tons, and it is one of the largest aluminum material product enterprises at home and abroad. Its micro-channel flat tube products are also one of the domestic and foreign brands.

Learn more >>

15 years of production and manufacturing experience

Capacity of 30,000 tons

Aluminum products are exported to more than 20 countries and regions in Europe and America

Accumulated customer service

News

The company adheres to the "integrity-based, quality-oriented, meticulous and meticulous, and pursuit of excellence" Quantity

Top Applications for Zn-Silflux Coating Flat Tubes in Building Materials

2026-03-03

Understanding the Importance of Coaxial Heat Exchanger Tubes in Building Materials

2026-02-28

Innovative Applications of Aluminum Round Tube Coils in Industrial Ventilation

2026-02-25

Enhancing Air Cooler Efficiency with Round Tubes: A Comprehensive Guide

2026-02-22

Cooperative customers

Our aluminum products are exported to more than 20 countries and regions in Europe and America

We are the main supporting suppliers for customers such as the German MAHLE Group, the Danfoss Group, Denso Japan, Daikin Air Conditioning Japan, Hyundai Motor Korea, Samsung Electronics, and LG Electronics. Domestic customers are mainly more than 200 automobile brands, including FAW Hongqi New Energy Vehicles, Ideal Auto, Dongfeng Group, GAC Group, SAIC Group, Chery Automobile, BYD Automobile, Geely Automobile, Great Wall Automobile, BAIC, etc.